Are you facing challenges with damaged or deteriorated sewer and stormwater pipelines? Pipeline Watertech, a renowned sewer and stormwater specialist, brings you the latest innovation in the field: pipe robotics and patch repairs.

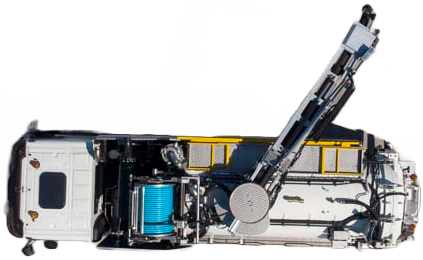

Pipe robotics is a groundbreaking technology that allows for the inspection and repair of pipelines using remote-controlled robots. These robots are equipped with advanced cameras and sensors, providing accurate and detailed information about the condition of the pipes. Pipeline Watertech harnesses the power of pipe robotics to diagnose pipeline issues quickly and efficiently, ensuring prompt and targeted repairs.

Patch repairs are an effective method for addressing localized damage or leaks in sewer and stormwater pipelines. This technique involves the application of specially formulated patching materials to seal and reinforce the damaged areas. Pipeline Watertech utilizes advanced patch repair solutions to restore the structural integrity of the pipelines, preventing further deterioration and ensuring long-lasting performance.

Inspection: Using pipe robotics, Pipeline Watertech conducts a thorough inspection of the pipelines. The remotely operated robots navigate through the pipes, capturing high-resolution images and collecting data on the condition of the infrastructure. This detailed assessment enables us to identify specific areas that require patch repairs.

Preparation: Before applying the patches, our team prepares the damaged areas by cleaning and removing any debris or contaminants. This step ensures proper adhesion and maximizes the effectiveness of the patch repair.

Patch Application: Pipeline Watertech utilizes advanced patch repair materials that are specifically designed for sewer and stormwater pipelines. These materials are applied to the damaged areas, creating a strong and durable seal. The patches conform to the shape of the pipe, providing a seamless and reliable repair solution.

Quality Assurance: To ensure the effectiveness of the patch repairs, we conduct comprehensive inspections using pipe robotics. This step verifies the success of the repair process and ensures the restored pipeline meets the highest industry standards.

Time and Cost Efficiency: Pipe robotics enable swift and accurate inspections, reducing the time required to diagnose pipeline issues. Additionally, patch repairs offer a cost-effective alternative to extensive pipeline replacement, saving you money on excavation and construction expenses.

Targeted Repairs: Pipe robotics allow for precise identification of damaged areas, enabling targeted patch repairs. This approach eliminates the need for unnecessary repairs, optimizing resource allocation and minimizing disruptions.

Durability and Reliability: Patch repairs reinforce the damaged sections of the pipeline, restoring their structural integrity. The materials used in patching are specifically formulated to withstand the harsh conditions of sewer and stormwater systems, ensuring long-lasting performance.

Minimized Disruptions: With pipe robotics and patch repairs, Pipeline Watertech minimizes disruptions to your property and the surrounding area. These non-intrusive techniques eliminate the need for extensive excavation, reducing noise, dust, and inconvenience for residents, businesses, and commuters.

Pipeline Watertech is a trusted leader in the sewer and stormwater industry, specializing in pipe robotics and patch repairs. Our advanced technology and experienced team ensure efficient and reliable solutions for your pipeline rehabilitation needs. Don’t let damaged pipelines compromise your operations or cause unnecessary disruptions. Contact Pipeline Watertech today to schedule a consultation and experience the transformative benefits of pipe robotics and patch repairs for your sewer and stormwater systems.

Let's start the conversation about how we can help you optimize your sewer and stormwater systems, minimize disruptions, and enhance the efficiency and reliability of your infrastructure. We look forward to hearing from you soon!